NoWax S

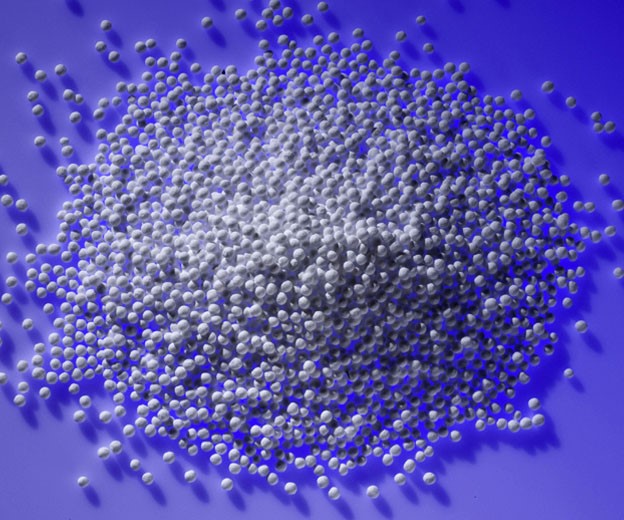

A solid organic paraffin and asphaltene inhibitor which has proven effective in controlling and/or removing paraffin and asphaltene problems. NoWax S is available in two forms-solid pellets and encapsulated spheres. These products are specially formulated to provide long term, uniform feed back for more effective control. NoWax S can be used in conjunction with paraffin solvents for optimization of paraffin/asphaltene removal and long term prevention.

ScalStop S

Solid organic phosphonate scale inhibitor which has proven effective in controlling calcium, barium and strontium scales. NoWax S is available in encapsulated spheres, which can be applied with the support agent. These products are specially formulated to provide long term, uniform inhibitor feed back for more effective scale control.

Geo-CIS- S

The primary usage of Geo-CIS is in applications as corrosion inhibitors effective against H2S and CO2 corrosions. It has been proven to be effective in preventing sulfide stress cracking or hydrogen embrittlement in rod parts. Geo-CIS is a solid inhibitor with a blend of components which are effective over a wide range of brines and temperatures up to 120 °C. The secondary usage applications are as a detergent, clay & shale stabilizer, packer fluid inhibitor. In addition, Geo-CIS will also diminish hydrogen sulfide and slime deposition. Geo-CIS is available in encapsulated spheres, which can be applied with the support agent. These products are specially formulated to provide long term, uniform inhibitor feedback. Over 60% of the GeoCIS product is available for preventing corrosion

GEOSAFE solid inhibitors are made up by carrier spheres, especially developed with porosity and permeability features, which inside their structure contain the liquid active inhibitor ingredient. This liquid inhibitor is slowly released from the inside of the particle, while the well is in production. This means that, as the production fluid comes into contact with the GEOSAFE solid inhibitor, the chemical in charge of the inhibition flows from inside the sphere, inhibiting the formation against paraffins, scale incrustations, corrosion, SH2, etc. Thus, it is the production of the well that determine amount of inhibitor is necessary, optimizing its efficiency. No contact time is required to achieve such inhibition, but rather it is the well flow rate that determines the amount of chemical released. Only a small amount of inhibitor is necessary, optimizing it’s efficiency. No contact time is required to achieve such inhibition, but rather it is the well flow rate that determines the amount of chemical released. Below is a link for a detailed discussion of the solid inhibitors

APPLICATIONS

Fracturing Operations: The most appropriate time to apply the solid inhibitors, since the inhibition begins from the moment the well is put into production. When added to the fracture or gravel pack, the greatest long- term inhibition is achieved. The use of solids in recovery treatments is also advantageous, and any subsequent fracture or gravel pack is an excellent opportunity to extend the inhibition protection. The selection of the size and shape of the microspheres allows the solids to be applied together with the proppant, and they are easily incorporated in the fracture work, where they can be dosed in the blender or in the hopper. Then, both are introduced into the formation by fracture pumping. As the production fluids circulate through the solids, the inhibitor is released.

Location of the solid in the fracture:

GEOSAFE solid inhibitors developed for fracture treatments have a mesh particle size of 120 to 150, so they will tend to occupy the available spaces between the grains of the proppant support agent. This means that, while they are settling, the solid inhibitor spheres are trapped in the bed of the proppant support agent.

Low viscosity fluids:

During the fracture operation, the grains of the proppant support agent settle down forming a bank that fills the width of the fracture. In the following stages, the grains of the proppant agent are placed on top and settle at the back of the pack. Thus, it is recommended to focus the treatment with high concentrations of solid inhibitor in the first half of the fracture treatment and reduce its concentration in the subsequent steps.

High viscosity fluids:

During the fracture operation, the proppant support agent is suspended in the fracture fluid, achieving deeper penetration, and it is distributed along the width and height of the fracture. Thus, it is recommended to use solid inhibitors with a uniform dosage in every step where the proppant agent is applied.

Solid with liquids:

Both types of chemicals can be used (solid as well as liquid). In addition, different types of solid inhibitors can be mixed in the blender together with the support agent.